Lean manufacturing tool

Data: 3.03.2018 / Rating: 4.7 / Views: 941Gallery of Video:

Gallery of Images:

Lean manufacturing tool

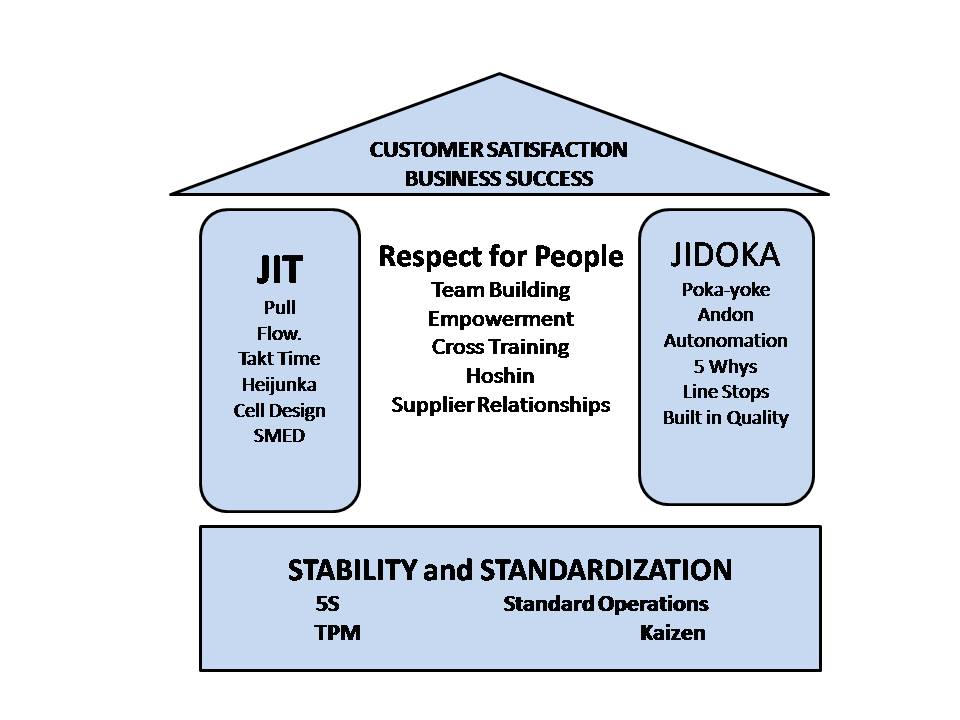

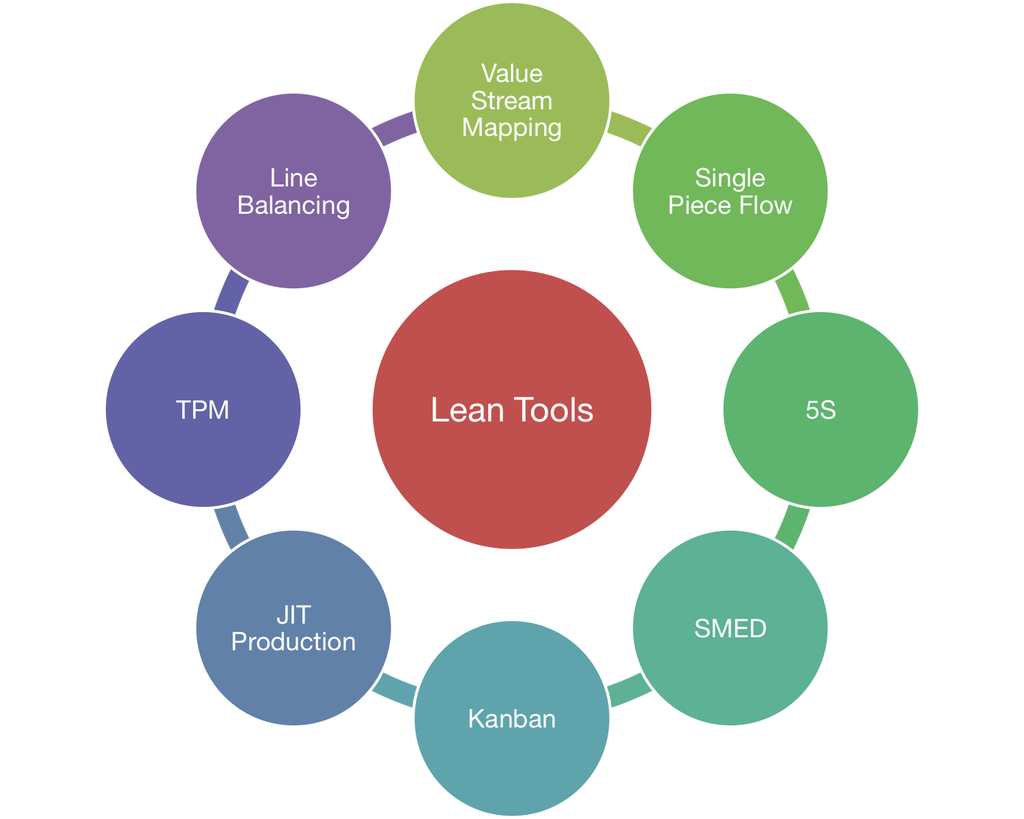

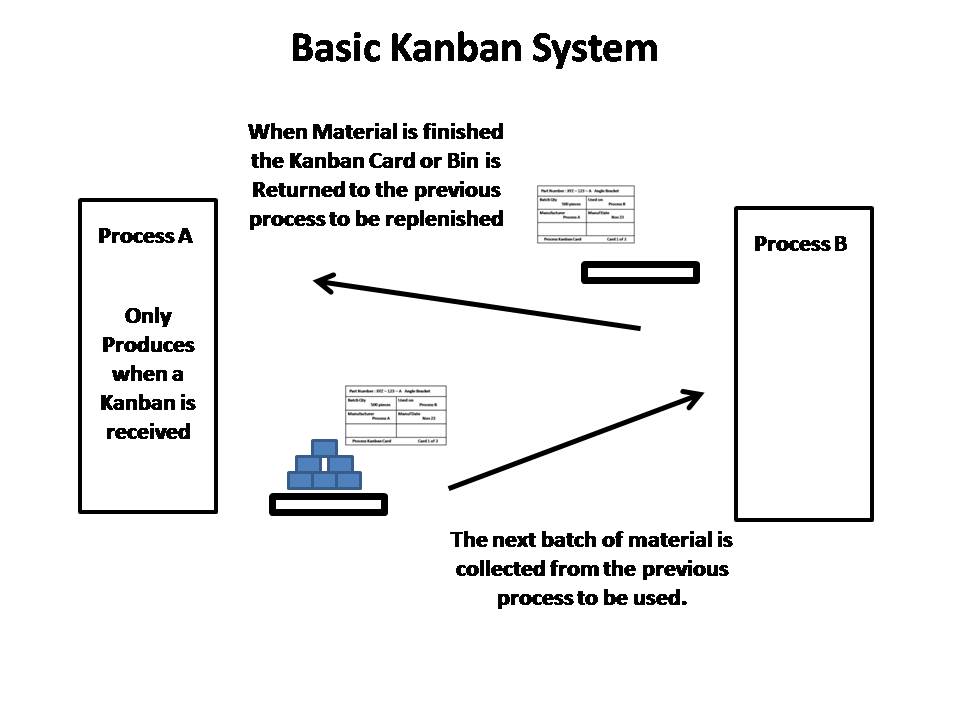

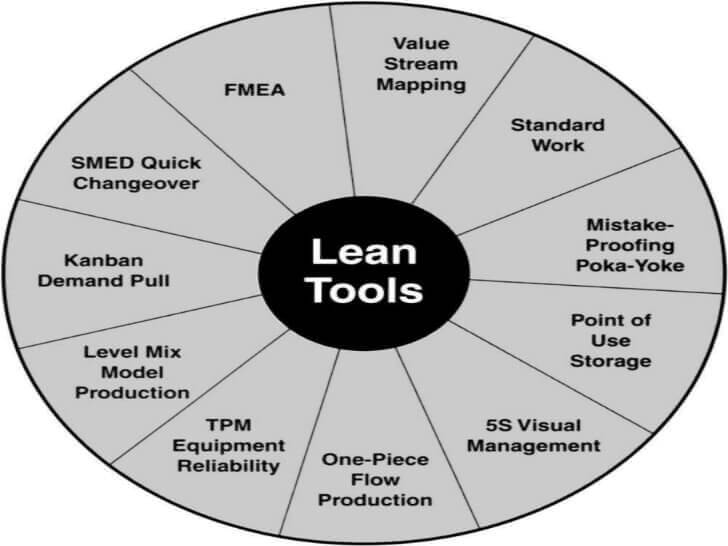

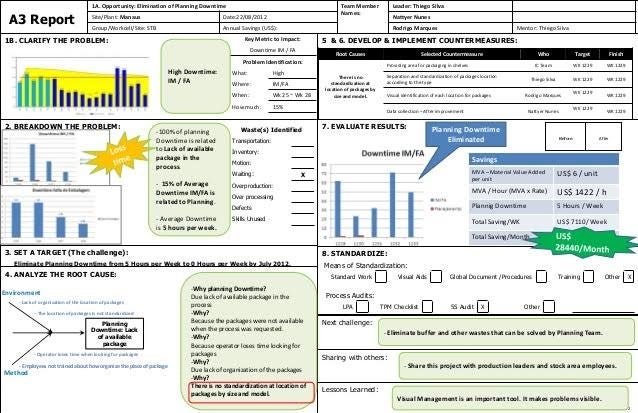

iv ABSTRACT LEAN MANUFACTURING TOOLS AND TECHNIQUES IN THE PROCESS INDUSTRY WITH A FOCUS ON STEEL Fawaz Abdullah, PhD University of Pittsburgh, 2003 Steel Industry and Lean Manufacturing: See Metal Producers and the article Running Steel Lean Stockroom Location Systems: There are many methods for deciding where to put parts within a stockroom, and there are plusses minuses for each. Our assessment tool for Lean Manufacturing. A commonsense, simple approach. Available as a free spreadsheet download. A popular misconception is that lean is suited only for manufacturing. Lean applies in every business and every process. It is not a tactic or a cost reduction program, but a way of thinking and acting for an entire organization. Lean Manufacturing Tools shows what the various lean tools are and how to implement them within the philosophy of Lean Manufacturing. This includes ideas such as Just in Time (JIT), 5S, Kanban, and SMED to name just a few. Ergonomics As a Lean Manufacturing Tool for Improvements in a Manufacturing Company Prof. Rosnah Mohd Yusuff Department of Mechanical and Manufacturing Engineering, Faculty of Engineering, University Putra Malaysia rosnahmy@upm. my Nor Suhada Abdullah Lean Manufacturing Tools and Techniques With companies and manufacturing units getting upgraded to newer and more efficient practices, it becomes evident that theres a great need for manufacturing tools and techniques to improve this situation. Manufacturing is gaining momentum as the world. 5 Lean Manufacturing Tools that Work 5 Lean Manufacturing Tools that Work Email this page Share this Page. Floor Tape; Industrial Label Printer; Industrial label printers are another great lean manufacturing tool that many companies use to improve efficiency. An industrial label printer is a printer that has the. Lean Manufacturing Assessment TWELVE ELEMENTS OF LEAN MANUFACTURING Lean Manufacturing consists of three management areas made up of 12 elements. Programa de mejora continua, Link de la pagina: especificaciones en la parte de productos. Implementation of Lean Manufacturing Tools in Garment Manufacturing Process Focusing Sewing Section of Mens Shirt Naresh Paneru Masters thesis we provide tools for lean manufacturing toyota production system easy, simple, and powerful. 5S Audit Checklist, Red Tag Log, and more 5S tools for Lean Manufacturing, Office 5S, or any 6S or 5 S lean program. Download 5S Scorecard and 5S Audit Form. Thumbnail descriptions of 40 tools and techniques associated with Lean. Lean production or lean manufacturing is a systematic method for the elimination of wastes within a manufacturing process. This may include wastes created through unevenness in work loads, overburden and any work that does not add value. we provide tools for lean manufacturing toyota production system easy, simple, and powerful. The Lean Manufacturing tools help product designers and manufacturers identify waste that eats into customer value and slashes profits. Every company has a different focus for lean initiatives, but successful strategies all depend on data. CribMaster can provide actionable intelligence. Lean Manufacturing PDF to download for free! Start to use Lean Manufacturing PDF that works. The best resources for Lean Management. lean tools allowed for a better understanding of the waste that was in the production line of lean manufacturing and the steps to implement them to ensure that they are on the leading a tool for developing standardized work; Measurement and analysis to Free online process improvement and quality improvement toolkit and toolbox using Lean Six Sigma or 8Discipline method. Lean manufacturing or lean production, often simply lean, is a systematic method for waste minimization (Muda) within a manufacturing system without sacrificing productivity. Lean also takes into account waste created through overburden ( Muri ). As a lean tool, 5S is used in many industries, including manufacturing, software, and healthcare. It can be one of the easiest lean tools to start with, and it can be used with Kaizen and Kanban to create the most efficient workplace possible. Lean manufacturing Tool for Productivity EnhancementCase Study Free download as PDF File (. This article explains the philosophy of LEAN Manufacturing in a practical way. After reading you will understand the basics of this powerful quality management tool. LEAN Manufacturing or LEAN Management originates from the Japanese car manufacturer Toyota. LEAN Manufacturing literally means lean production. Home Blog Resources Lean Templates 30 Free Lean Tools, Templates Examples Greetings! Here youll find free, high quality Lean Templates from GoLeanSixSigma. Lean Supermarket selling lean manufacturing products including 5S, kaizen, TPM, value stream mapping, kanban system, lean training videos, 5S tools and products. Order lean manufacturing production boards from Magnatag. com to keep a visual of scheduling, maintenance, and more. Orders ship in 3 business days or less. Lean Manufacturing Find a Course There is a misconception that Lean and Lean Six Sigma methodologies are only applicable to manufacturing or supply chain processes. This tool also can be a part of a Kaizen cycle, incorporated within the Analyze and Improve phases. An example of how the For processes involving cycle times, such as manufacturing or incident management, the asis cycle time can be captured in the Measure phase. I just finished reading a book by Micheal L. Brief Definitions of Lean Manufacturing Tools Methods Used In Production and Manufacturing Process Improvements Under the System of Lean Manufacturing The challenge is the lean implementation, he explains training the workforce so they understand lean principles, developing a culture that is open to change and problemsolving. Those are what is most important, he says, not the tool. At Technicut Tool, we implement the 5s standard methodology to maximize spatial effectiveness. In doing so, we create an environment that promotes organization, cleanliness, and efficiency in order to actualize potential productivity. Read our white paper to learn how to optimize productivity, and implement a 5s workplace organization program to create lean manufacturing processes. Only at the official Lista site. Lean provides tools and processes to eliminate waste from the manufacturing process resulting in improved efficiency, effectiveness, and profitability. We offer 5S Supplies, Lean Products and other 5s lean manufacturing, 5s training supplies at the best prices available on the market. in this video, you will lean what is lean manufacturing. how lean manufacturing cn help you reduce the cost of operation. this video also Explain to you how. Lean manufacturing is a movement established by Toyota Production Systems and is centered on clarifying what brings value by reducing everything else. 5 Necessary Lean Manufacturing Tools California's Manufacturing Network Exploring Lean. There are a lot of great ideas to explore in lean. One way to start is to survey the most important lean tools, with a brief description and short explanation of how each tool can improve your manufacturing operations. In this followup story to our case study about Phase 2 Medical Manufacturing, Inc. , the company faces an enviable dilemma: because the lean transformation has spurred strong sales growth, Phase 2 needs a new or expanded parts warehouse. By: Marchwinski, Chet May 16, 2014 Case Studies. Lean Manufacturing even impacts Six Sigma, as Lean Six Sigma has evolved into an approach taken to reduce waste, improve efficiency and drive profitability. Lean as a Tool Lean Manufacturing: The latest term used to describe a philosophy of manufacturing committed to the elimination of waste from the entire value stream, and to Continuous Improvement in all things. Waste is defined as anything that does not add value from the customers perspective. Lean Tools The following is a collection of 25 essential lean tools. Each tool is distilled into a simple description of what it is and how it helps. Value stream mapping adalah tool grafik dalam Lean Manufacturing yang membantu melihat flow material dan informasi saat produk berjalan melalui keseluruhan bisnis proses yang menciptakan value mulai dari raw material sampai diantar ke customer. Lean manufacturing is a system that aims to eliminate waste, improve quality, and increase profits by creating value based on customer needs. Businesses gain the greatest benefit from 5S when it is used with other lean tools. Creating a great looking tool shadow board wasnt exactly written into your contract now was it! Experts in Effective Lean Manufacturing Open Los Angeles Division. Leaders in lean manufacturing solutions, Lean 5S Products, announce their expansion to a new Read More. An important question to consider when. Vidmar offers a comprehensive selection of lean manufacturing and 5s storage solutions. Learn more about our wide range of storage products. Implementation selected tools of Lean Manufacturing 5 1. Aim and scope of the project The aim of the project is the implementation of manufacturing tools to improve the Lean Manufacturing: Principles, Tools, and Methods 1 2 Bosch Rexroth Corporation In todays manufacturing environment, assembly work is routinely characterized by short production cycles and The scheme Correct Arrangement of the Tool from a CIT instruction sheet, . Although the origins of the 5S methodology are in manufacturing, it can also be applied to knowledge economy work, with information, Lean manufacturing; Muda;

Related Images:

- The time pandemonium

- Fall of max payne

- Siddhu 2 lotus

- The Return of Depression Economics

- Script Manager SManager

- Dont pass me by

- Transformers hsbs yify

- Fl studio producer edition 11 0 final r2r chingliu

- Vst x free

- Tech N9ne flac

- The Sexual Desires of Dakota Skye

- Age of speed

- Life of pi french

- South park the stick ps3

- Pure driving rock

- Cannibal corpse discogra

- Kiseijuu 720 02

- Met art helen

- Of the atom

- Crank jacob van hage

- American horror story s2

- Double jane darling

- The get healthy

- Cold case s02

- Black market android

- Leonard cohen album

- Whiteout dual audio

- Dont miss a

- The lost city 1935

- Legend the ends

- Best you two

- Best of top gear

- Ncis orleans s01e04

- Make My Wife Jealous

- Shot glasses 2008

- NeYo Let Me Love You Until You Learn To Love Yourself

- Chronicle ita mkv

- My best bodyguard

- Driver sound card

- The walking dead 4x15

- Like a boss

- Addicted in afghanistan

- Into the wild dvd5

- A matter of class

- Dre dog jim jones

- Star wars 1080p brrip

- Jai jai kar

- Lionel richi all night

- Quando tutto cambia

- Manuel lisa ann

- Terminate g unit

- Runtastic Road Bike

- Private practice s05e20

- Rush hour movie 3

- Welcome to collinwood

- Le rouge le noir

- Tiesto club life 227

- Dead island ISO

- Sea gold season

- First Day Of My Life

- Call of duty 5 of pc game

- Bond live at the royal albert hall

- 40 days of riot

- Jackass bad grandpa dvdrip

- Nba league pass

- Beauty and the least

- Dual audio 720p english movies

- Fedde le grand love never

- PSP Certification Study Guide

- Jk rowling harry potter 1 7

- Jada stevens monsters of cock

- Lil Wayne con

- Freddy sort de la nuit

- Justice a cross the universe

- Led zeppelin 1977

- Logic pro 1007

- Pool party fun

- X art still with

- American horror story s01e09 web dl

- Monster vs aliens 720

- Charlie Chaplin series

- Breaking bad season 5 french